Exploring Bowstring Trusses in Historic Structures: VERTEX’s Insights

This is the third in a series of blog posts on historic and antiquated structural and façade systems. As discussed in our previous posts on iron and riveted steel structures and on terra cotta facades, inspection of these historic systems requires specialized knowledge from experienced forensic experts who can assist with the assessment, repair and retrofit of these systems.

This post focuses on wooden bowstring trusses as an example of such a historical system.

Wood Construction Fundamentals

Since pre-historic times, the use of wood, a naturally occurring and often abundant material, has been fundamental to the development of construction. Starting with lean-to’s, tents and huts and evolving to modern midrise buildings, the history of wood construction is nearly tantamount to the history of construction itself. Wood as a construction material is valued for its high strength, lightweight, ease of access and ease of use. Wood can be effectively worked with simple hand tools, even in remote and inhospitable locations where, up until the past century, the use of power tools would have been impossible or impractical. Wood has been used for heavy timber framing as well as modern stick framing, and used ubiquitously in single-family home construction throughout the United States. In some cases, wood has been used to create long-span structures, such as bridges, warehouses and airport hangers. One such long-span structure modality is the bowstring truss.

The History of Bowstring Trusses

Bowstring trusses were widely used in construction in the United States from around 1900 to 1950. Due to its inherent adaptability, these trusses allowed for the creation of large open span spaces without the need for internal columns, a special condition desirable for many applications. Bowstring trusses often span between 50 and 100 feet between support walls or columns. Individual trusses are commonly spaced at approximately 20 to 25 feet apart, and the trusses are interconnected with wooden lateral bracing members (Fig. 1 below).

Figure 1: Wooden bowstring trusses

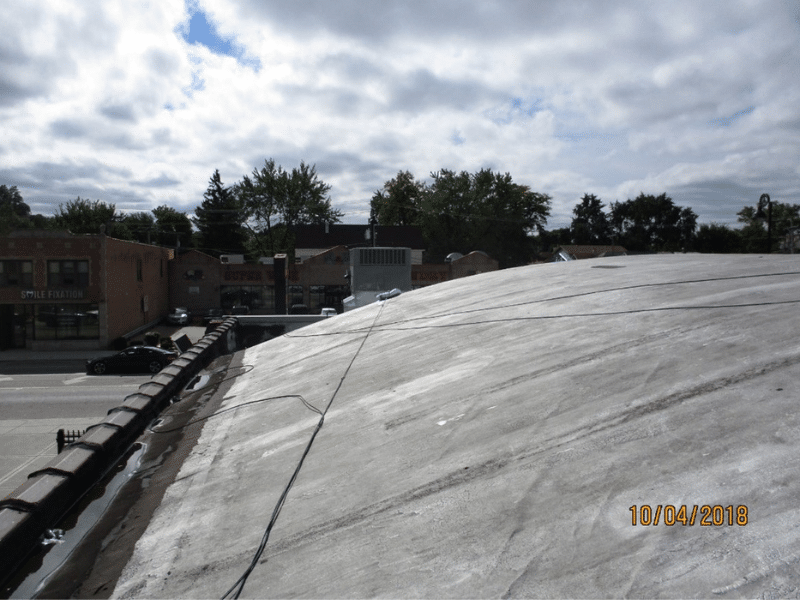

Historically, the open span spaces afforded by bowstring construction were commonly used in manufacturing and warehousing applications. More recently, modern steel structures have largely supplanted bowstring truss structures for manufacturing and warehousing applications, but existing wooden bowstring truss buildings remain in service. Today, historical bowstring truss buildings have become desirable as public gathering spaces, such as retail spaces, restaurants and bars where the visible wooden trusses overhead are considered a desirable aesthetic feature. From the exterior, their distinct barrel shaped roofs (Fig. 2 below) can often identify bowstring truss buildings.

Figure 2: Distinct barrel shape of a bowstring truss building

Construction of a Bowstring Truss

As the name suggests, bowstring trusses have the shape of an upturned bow, with a curved top chord and a straight bottom chord. The top and bottom chords are constructed of a series of individual heavy wood timber boards, or “plies.” The top and bottom chords are interconnected by vertical or diagonally oriented web framing. This web framing comes in two common forms: truss framing (Fig. 1) or lattice framing (Fig. 3 and 4 below). The wooden plies of a bowstring truss are interconnected using steel bolt fasteners and splice plates. The combination of the chord members and web framing allow the trusses to effectively resist flexural and shear loading.

Figure 3: Wooden bowstring lattice trusses

Figure 4: Wooden bowstring lattice trusses

Forensic Issues in Bowstring Truss Structures

Like all wooden construction, bowstring trusses are susceptible to fire damage. Once damaged from a fire, the load-carrying capacity of a wood truss may be reduced. Experienced forensic experts can evaluate such damage and provide repair recommendations. Repairs to bowstring trusses can include reinforcing or replacing individual plies of a truss. In some cases, total replacement of entire trusses may be a more cost-effective solution (Fig. 5 below).

Figure 5: Fire damaged bowstring truss members

In addition to susceptibility to fire, many historical wooden bowstring trusses do not meet modern building code requirements for snow and wind loading. In particular, wooden bowstring trusses may be over-stressed by unbalanced snow loading. Unbalanced snow loading is a condition that occurs when heavy snow loads build up on only one half or one section of a roof structure. This condition commonly occurs when heavy snowfall combines with strong winds, which push or redistribute the snow to one side of a structure. This loading condition was not fully understood nor addressed in historical building codes when many bowstring truss buildings were constructed. When subjected to such overloading, wooden bowstring trusses may experience fractured members (Fig. 6 below) and the roof structure may sag or even collapse.

Figure 6: Fractured bowstring truss member

Bowstring trusses may also experience long-term deterioration due to rot or insect attack. Wood rot most commonly occurs in areas of elevated moisture. For this reason, maintaining an effective roofing membrane above wooden framing is critical. Particular care should be invested in ensuring that water does not intrude at roofing penetrations, such as at roof drainpipes and mechanical ductwork locations.

A detailed structural analysis model of a wooden bowstring truss can done to determine if an existing historical bowstring truss is adequate for modern loading. In cases where trusses are found to be deficient, the installation of additional wooden plies, or more commonly, by reinforcing the bottom chord of the truss by securing two parallel steel rods (Fig. 7 below), to the existing splice plates of the truss, which can increase the trusses load capacity. The splice plates may also require reinforcement or replacement to accommodate the connection of the steel rods and provide sufficient area for bolt connections to transfer loading between the steel rods and the bearing of the truss.

Figure 7: Wooden bowstring truss reinforced with a steel tie rod.

How Vertex Can Help

VERTEX has forensic experts as well as cost-estimating professionals skilled in evaluating the unique characteristics of wooden bowstring structures and other historic elements. For more information on how to maintain, repair and restore them, contact Isaac Gaetz or submit an inquiry on our contact form.

In Part 4 of this series, we will discuss Historical Masonry Construction.