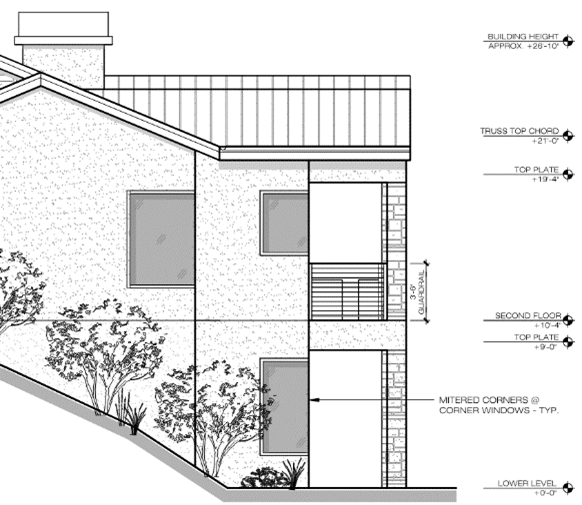

VERTEX provides structural design services for many industrial, commercial, and residential properties around the globe. Recently, VERTEX had the opportunity to work on a luxury two-story, split-level custom residential property located in Northern California’s Napa Valley that required a unique approach to its structural design in regards to the projects geographic location due to potential seismicity in the projects environment. As with every multi-story custom residential project, this design presented its own unique challenges. The property was to be designed to include two covered decks, one of which is shown in Figure 1.

While the design of elevated decks is typically a straight-forward process, the high seismicity prevalent in the Napa Valley required creative thinking to provide a code-compliant result.

Unique Challenges

One of the main challenges was for VERTEX to develop a Lateral Force Resisting System (LFRS) that was safe and sound for the decks, while still meeting the architectural aesthetics of the project. As can be seen in Figure 1, the decks were to have their vertical supports only on the ends, and those supports had to be relatively thin. While the main portion of the residence was designed using plywood shear walls, the decks could not be designed with regular plywood shear walls due to shear wall aspect ratio limitations per the National Design Specifications (NDS), which is the California Building Code’s referenced standard for wood/timber design. The NDS allows plywood shear wall aspect ratios of up to 3.5 to 1 (Height-to-Width). The vertical panels supporting the deck are a full story (approximately 10 ft) in height, but are only 12” in width, thus exceeding the maximum allowed aspect ratio permitted by the code for plywood shear walls.

VERTEX solved this issue by evaluating alternative lateral systems, and two options were investigated.

Option One

The first option was to design a lateral bracing mechanism using an Ordinary Steel Moment Frame (OSMF), however, this option would have required more material and construction labor because it involves building with custom-fabricated steel. This option would have also required welding on site as well as a large concrete foundation system to support the steel-framed columns.

Option Two

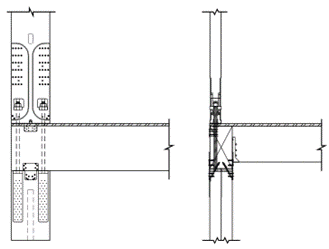

The second option investigated was a proprietary shear wall panel. Proprietary shear wall panels are pre-fabricated elements that have been structurally evaluated and tested to carry a given amount of force, and as such, they do not need to meet the height-to-width aspect ratio requirements for plywood-sheathed shear walls. An example of such a product is the Strong-Wall (manufactured by Simpson Strong-Tie).

For this design, 12” wide Simpson Strong-Wall products were specified after ascertaining that the strong walls had adequate capacity to safely resist the decks’ lateral demands. The final design involved using two sets of strong walls (see Figure 3); the roof covering the deck was supported by a 12” wide strong-wall in a stacked configuration, and the deck itself was supported by a second, separate 12” wide strong-wall that was single-story, thus utilizing a “back-to-back” strong-wall configuration. Although the stacked and back-to-back strong wall configuration required a larger concrete foundation, it resulted in a better overall design compared to what would have been required to adequately anchor a steel frame.

By utilizing strong walls in a stacked and back-to-back configuration, VERTEX was able to provide the client an economic solution that met both the architectural aesthetics of the project and was easy to construct.

Author: Tadei Shayo

HOW CAN VERTEX HELP?

Selecting a cohesive and coordinated design team is not easy but the effort is well worth it when one considers these professionals hold the project’s success in their hands. As an Owner’s Representative, Structural Engineers and Forensic Architects VERTEX can be a guide through this selection process to assure a strong start on any project.

To learn more about VERTEX’s Services or to speak with an Expert, call 888.298.5162 or submit an inquiry.

Author: Tadei Shayo