Piping failures can lead to a wide spectrum of losses and damage to property. These losses can occur in residential, commercial, and industrial water distribution and sanitary waste plumbing systems, HVAC systems, manufacturing process systems as well as several other critical plumbing systems that can be found in everyday life. These failures can lead to potentially millions of dollars in property damage, especially when the piping contains hazardous materials like sanitary waste and petroleum products. Water and freeze property damage alone made up 23.8 % of national residential insurance claims in 2018. [1]

A common piping failure is the rupture of the piping wall due to excessive stress. This piping failure mode is common in freeze failures and results in a characteristic “fish mouth” appearance, named for the split and deformation of the pipe wall which resembles a fish mouth as can be seen in the photos below.

How and Why Does Piping Rupture?

Piping ruptures are typically a direct result of an over-pressurization event.

Freeze Failure

A freeze failure is a common type of over-pressurization event. As water freezes its volume increases resulting in an internal piping pressure increase between the ice formation inside the pipe and closed valves. The increase in pressure results in increased stress in the piping wall and can exceed the strength of the piping material, ultimately leading to failure. Prevention methods for freezing pipes include insulative pipe wrap, heat trace (electric heater wrap), and the addition of anti-freeze (glycol) to water to lower the freezing temperature. The table below shows freezing points of different concentrations of Propylene Glycol-based water solutions.

Freezing Point of Propylene Glycol Based Water Solutions [2]

| Propylene Glycol Solution (%) | by mass | 0 | 10 | 20 | 30 | 40 | 50 | 60 |

| by volume | 0 | 10 | 19 | 29 | 40 | 50 | 60 | |

| Temperature | °F | 32 | 29 | 18 | 7 | -8 | -29 | -55 |

| °C | 0 | -3 | -8 | -14 | -22 | -34 | -48 |

Water Hammer

Another common over-pressurization event is “water hammer”. Water hammer events in piping systems occur when a rapid deceleration of flowing liquid results in a pressure spike or wave within the pipe. Water hammer, despite its name, is not only limited to water piping but can occur with any liquid medium. This is most common in long straight runs of pipe where the fluid has less resistance and has a chance to increase velocity. The change in pressure (∆P) resulting from a water hammer event in a pipe is:

ΔP = 0.070 Δv / Δt

- Δv is the change in fluid velocity

- Δt is the change in time (i.e.: valve close time)

Prevention of water hammer is achieved by avoiding unnecessary long straight runs of pipe, especially close to fast-acting valves, or by installing a water hammer arrestor. A Water hammer arrestor consists of an energy absorber, typically a spring-loaded bladder. This allows the energy of the pressure wave to be dissipated safely and not by piping or fittings.

These over-pressurization events can be aided by such factors as material selection and environmental conditions. Pipe materials must be selected to fit the working fluid and pressures needed for a specific system. Environmental factors must also be considered when designing piping systems. External conditions such as temperature, UV radiation from the sun, and exposure to certain chemicals can cause material degradation or embrittlement can result in piping failure.

Piping Strength and Stress

Pipe (Material) Strength

All materials have specific properties, such as material strength. The strength of a material is its ability to withstand an applied load without failure or plastic deformation. The field of strength of materials deals with forces and deformations that result from their acting on a material. Two important indications of the strength of a material include minimum yield strength and ultimate tensile strength, both measured in units of pressure or pounds per square inch (PSI). Minimum yield strength is the tensile stress needed to produce elongation of a material of 0.5%. [3] Ultimate tensile strength is the maximum stress that can be endured by a material in tension. [4]

Piping Stress

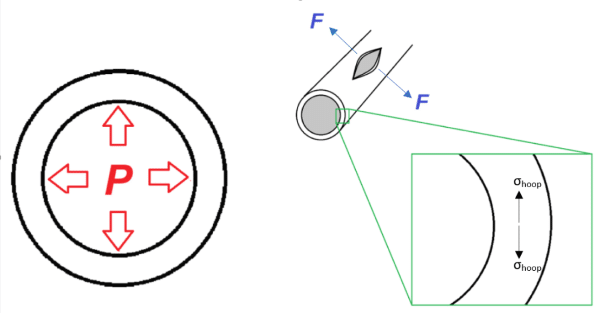

The forces acting on a material, in this case, pipes, cause stress in the pipe. In pipes, the pressure of the fluid exerts a force in all directions. In pipe ruptures, the type of stress that is most critical is known as hoop stress (σhoop). Hoop stress occurs from the resultant forces acting in the normal direction or tangentially to the radius of the pipe as shown in the diagrams below.

As the forces or pressure in the pipe increase, the hoop stress also increases. When the stresses in the pipe rise to the minimum yield strength the pipe will begin to deform, usually in the form of a bulge. If the hoop stress continues to increase and exceeds the ultimate yield strength, that is when failure or rupture will occur.

How Can VERTEX Help?

Plumbing losses come in all shapes and sizes. VERTEX’s team of mechanical engineers has expertise in all aspects of plumbing system design, installation, and failure analysis. We are available to analyze failures and existing plumbing systems to help identify potential installation, operational or maintenance challenges which could lead to future pipe and plumbing component failures.

To learn more about VERTEX’s Forensic Engineering services or to speak with an Engineering Expert, call 888.298.5162 or submit an inquiry.

Author

Anthony Timpanaro, PE

Forensic Mechanical Engineer