The Challenges of Large Loss Claims

Large loss claims can originate from a variety of sites, including but not limited to: oil and gas (O&G) facilities, gasoline stations, industrial/manufacturing facilities, pipelines, dry cleaning operations, and large-scale residential buildings. Types of pollution events that can lead to large loss claims include petroleum and produced water releases, chlorinated solvent releases, and mold and asbestos releases. Large losses often lead to emergency response actions, which incur high costs in an expedited timeline.

Typical Examples of Large Loss Sites:

Gasoline Stations

Releases from gasoline stations can be sudden, large releases or small releases that go undetected for some time. The majority of gasoline releases occur due to subsurface failures of underground storage tank (UST) systems due to wear (i.e. corrosion holes, gasket failures, line failures, etc.) or due to faulty installation of UST components. These subgrade releases often can go undetected by the USTs release recognition mechanisms due to the release being below a leak detection method’s threshold or due to poor site management, allowing a small leak to cumulate to an eventual large scale release. It’s also not uncommon for sudden catastrophic releases to occur from tank overfills, filling operations during scheduled tank system maintenance events, or by utility or drilling work that punctures a pipe or tank.

The challenges of large volume gas station releases are many. First, remedial work often takes place within an active business property, which can impede emergency response/remedial work and drive up costs. Second, it’s very common gasoline stations have historic releases that have co-mingled with a large scale release that were either unknown or not addressed by the responsible. When these situations are encountered, it becomes complicated to remediate the subject loss from historical impacts and to determine who is liable for costs incurred. When responding to a large loss at a gasoline station, it is imperative to review state databases for historical releases and/or groundwater impacts, which may aid in developing an allocation between historic and new losses. Additionally, VERTEX recommends that groundwater sampling events include analyzing for markers compounds that may allow for dating of a release, such lead scavengers and methyl-t-butyl ether (MTBE) for historical releases and ethanol for current releases If these compounds are detected in groundwater samples, this data can be used to develop an allocation between historic and new losses.

Bulk Oil & Gas Storage Facilities

Losses involving the oil and gas extraction industry are generally large in terms of the volume of released product, as well as the cost for remediation. Bulk storage facilities are typically located near a body of water which allows easy access for importing and exporting of products, adding a layer of complexity to remediation if products enter the surface water body as surface water body releases tend to spread quickly and have the potential for harming large populations of native fauna and wildlife .

Due to the general scale of releases from these facilities, emergency response costs can be sizable and often involve State or Local agencies. Excavation of impacted material from these facilities can be costly and labor intensive as there are typically multiple underground transfer pipelines present requiring Hydro-Excavation and/or hand digging to ensure a subsurface line isn’t unintentionally struck resulting in a secondary release. Remedial activities often take several years to complete due to and often involve active remediation treatment systems such as groundwater pump and treat system and soil vapor extraction systems due to the access to potentially impacted media as a result of the amount of infrastructure present (e.g. non-involved ASTs, pipelines, etc.). Additionally, similar to releases from gas stations, most bulk storage facilities have historic releases, complicating the liability of remediating the loss.

Produced Water Disposal/Transfer Facilities and Petroleum Transfer Pipelines

Produced water is a byproduct of oil and gas extraction and is naturally occurring as most oil-and-gas bearing rock formations also contain water. Produced water generally has high concentrations of chlorides, dissolved petroleum hydrocarbon compounds, and radioactive isotopes. Disposing of produced water typically involves use of an injection well injection back into the ground at depths of approximately 8,000-9,000 feet. Prior to injection, produced water is storage in large above ground tanks and filtered to remove residual oil. Produced water can be transported to a disposal facility via vacuum truck or direct pipeline. Generally, these facilities are located in remote areas and are unmanned, which increases the risk of a release from a pipeline, storage tank or well head going unnoticed for some time. Remediation typically involves vacuum removal of standing fluids and large scale soil remediation.

Petroleum products can be transported to/from bulk storage facilities via underground pipelines. These pipelines have limited access points and cannot be monitored from the surface. Releases from underground pipelines may be the result of corrosion in the case of metal pipelines, general age and wear or over pressurization events resulting in pipe or seam failure. Pitting of metal pipelines may result in a slow release of a small amount of product over an extended period of time that goes unrecognized or a large scale one time release due to rupture. Often, ongoing releases are unknown until surface impacts are observed such as dying vegetation, surfacing/pooling product, or impacts to stormwater/sewer drainage features. Subsurface releases related to pipelines may travel along the exterior of the pipeline through gravel bedding greatly increasing the total liner impacted area. Transfer pipelines located at Bulk Storage Facilities also have the potential to impact surface water bodies. Remediation typically involves vacuum removal of standing fluids and large scale soil excavation/remediation.

The most common challenges for these facilities is they are often in remote areas and are un-manned. Releases have the potential to occur over lengthy periods of time until observed by a routine facility or line inspection, resulting in a slow release over a long period of time becoming a major remediation project. Increased costs associated with remediation at these facilities usually a result of the need to mobilize crews from several hours away for cleanup and, where off-site disposal of soil is needed, increasing transportation costs to and from the release site.

Agricultural Losses

Large scale agricultural losses can originate from fires, explosions, or extreme weather events. These events can lead to significant fertilizer chemical releases, which can impact surficial soils, surface waters, and sediments. Additionally, farms often accept wastewater biosolids, which typically include PFAS compounds. During extreme weather events, biosolid runoff can impact nearby water bodies with PFAS contamination.

The most common challenges for these facilities is they are often in remote areas and there is a limited availability of contractors and/or consultants to remediate the loss. Additionally, the losses can be physically large in size and impact a significant area of land and/or surface waters, which drive up the cost of the remediation.

Chemical Fires

Chemical storage and blending facilities often house hundreds of hazardous and non-hazardous chemicals in close proximity. A chemical facility that experiences a fire can not only be catastrophic for the facility, but can have serious environmental repercussions. Fire at these facilities present unique risks including the release of potentially toxic fumes which could require area evacuations and/or shelter-in-place orders and chemical reactions among stored materials resulting in explosions.

Emergency response activities for chemical fires can include mobilization of State and Local Hazardous Materials Response Teams and 24-hour Site and area wide air monitoring. Depending on the chemicals stored at the facility, affected soils, surface water and groundwater could be considered hazardous, greatly increasing the costs of handling and proper disposal. Increased laboratory analytical costs are also common as the presence of dozens or hundreds of stored chemicals requires a long list of analytes for evaluation and assessment as well as the byproducts of chemical combustion and comingling or residual chemicals and fire fighting water. In cases were Aqueous Film Forming Foam (AFFF) is utilized for fire suppression, there is a potential for Per- and Polyfluoroalkyl Substances (PFAS) impacts as a result of fire fighting efforts.

Microbial Growth and Cold Storage

Cold storage facilities, or refrigerated warehouses, store perishable or sensitive goods such as food, medicine, or even art work that requires a temperature controlled environment. Most commonly these facilities store perishable foods for packaging and distribution. These facilities relay on large scale Heating, Ventilation, and Air Conditioning (HVAC) systems and insulation to maintain required indoor temperatures for the integrity and shelf-life of the inventory. Ambient temperatures, HVAC failures and insufficient insulation can adversely affect the systems ability to maintain internal temperatures which can result in the buildup on condensation resulting in microbial growth.

Remediation challenges include simultaneous operations, which may result in remedial work being completed after hours increasing costs, and preservation of existing goods as well as potential business interruptions costs.

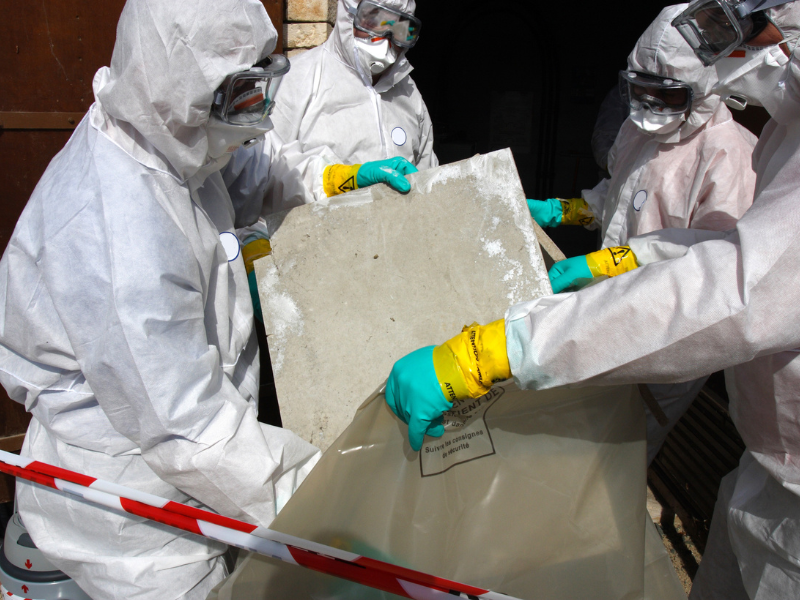

Asbestos

When a commercial or residential property suffers any type of loss, hidden hazards can make the recovery process more complicated and costly. One of the most common hidden hazards is asbestos, a material widely used in building products through the present date. Asbestos fibers are dangerous when disturbed and inhaled, creating serious health risks for workers and occupants. Beyond health concerns, failure to properly identify and handle asbestos can lead to regulatory penalties, project delays, and ballooning claim costs. In addition to the standard remediation and restoration costs, claim costs often include fees for occupant relocation/temporary living, replacement of appliances, HCAV units, contents, and business interruption (if applicable). Some common situations that create asbestos disturbances/losses include:

- Fire damage: High heat and firefighting activities can break apart asbestos-containing materials (ACMs).

- Water damage: Ceiling and wall collapses following flooding or pipe breaks may release asbestos fibers.

- Storm events: Wind or debris can damage siding, shingles, or older roofing materials that contain asbestos.

- Renovation and Demolition: Contractors performing renovations or demolition may unknowingly disturb ACMs. If ACMs are properly identified, abatement practices may be inadequate.

Early identification and proper planning help minimize both cost overruns and liability. Best practices on large losses should always include:

- Survey first: Always conduct a hazardous materials survey, or at the very least, an asbestos survey or sampling before conducting demolition or renovation. This is extremely important to keep in mind before conducting mitigation activities at a storm, fire, or flood loss.

- Bring in the experts: Licensed asbestos inspectors should be conducting sampling. Licensed asbestos abatement contractors are required for removal or stabilization.

- Clearance testing: Independent third-party air monitoring and inspections verify the site is safe before rebuilding.

- Coordinate early: Adjusters, restoration contractors, and environmental consultants should be aligned on scope and safety requirements from the start.

How Can VERTEX Help?

The Vertex Companies, LLC (VERTEX), with an experienced staff of professional engineers, professional geologists, and environmental scientists, can assist claim handers on to large loss claims. VERTEX has personnel across the country and can quickly get resources on the ground following climate related claims such as O&G facility/pipeline releases, sudden petroleum and dry cleaning releases, and large scale mold and asbestos releases. For more information, please contact Michael Bator at mbator@vertexeng.com.