If you have been following our series of articles about balcony inspection laws in California, you are well aware of the fact that water trapped inside unvented balcony soffits can result in damage to the interior wood structural components, which can lead to catastrophic, even deadly, collapse.

This was the case with a devastating balcony failure in Berkeley, CA, in 2015 that resulted in several deaths. In the aftermath of the incident, the city conducted 2,176 balcony inspections and found that 402 (19%) required repair. They concluded that “data reveals that deterioration of Exterior Elevated Elements (EEEs) is a significant problem and illustrates that a post-occupancy inspection program is critical to reducing the risk of failure of existing EEEs.”

The State of California has since addressed this danger with two new laws, SB 721 (passed in 2018) and SB 326 (passed in 2019), requiring periodic visual inspections of balcony structural elements. The laws state that if balconies have enclosed stucco soffits with wood framing (and there are a lot of them out there), they must be visually observed in order for inspectors to evaluate the condition of the interior structural elements.

As discussed in previous articles, meeting this requirement presents a challenge for many property owners. The traditional way to gaining visual access to the inside of the soffits can be quite destructive, costly, and labor-intensive. To help our clients with this issue, Xpera has developed a minimally invasive method to inspect the inside of the soffit.

We would like to introduce you to another attractive solution for owners and property managers: removable soffit vents. We will discuss vents more in a moment, but first, it is important to understand why ventilation of these structures is necessary.

Why are balcony soffits enclosed in the first place?

There are three major reasons why apartment or condominium developers would enclose the soffits on their buildings’ balconies and other EEEs:

- Aesthetics: To hide supporting joists that would detract from the building’s façade

- Weather Protection: To protect the structural components from exposure to the elements as part of the building’s water management design

- Pests: To prevent termites or other destructive pests from accessing wood-based components

The Problem with Enclosed EEEs & Moisture

Until California passed the recent emergency building code legislation, sealing wood joists inside a soffit with materials such as stucco was not considered to be a problem. The thinking was that with modern practices in manufacturing and construction, the wood components had already reached equilibrium moisture content (ECM). Therefore, there would be minimal warping and the wood would no longer carry (or release) excess moisture.

However, the Berkeley balcony collapse highlighted the risk of moisture accumulation inside a sealed soffit, whether it is the result of water intrusion from failed waterproofing or through vapor drive. That extra water has to go somewhere, and it often evaporates into vapor inside the soffit cavity after the wood and other materials are saturated.

It doesn’t stop there. The air capacity for water is dynamic, and it changes with temperature.

Here is what happens: When there is hot air inside a balcony soffit that has trapped moisture, its vapor capacity is high, and the air can hold a lot more moisture as vapor. Some of that water evaporates into the air inside the soffit. If there is a quick evening cooldown, the interior surface of the soffit becomes a lot cooler, and the interior air loses its vapor capacity.

It has no choice but to give up its water content on the surfaces in the form of condensation. This is because the air temperatures outside and inside the soffit are not in equilibrium.

The daily evaporation-condensation cycle inside these balcony soffits wreaks havoc on the interior wood structural elements, such as joists, plywood decking, hangers, and nails.

How Vented Soffits Help Solve Excess Moisture

Vents can help prevent vapor from condensing inside a soffit by allowing temperature and humidity equilibrium between the outside air and the inside air—around the clock and all year long. This avoids the daily evaporation-condensation cycle. Additionally, if a leak causes extra water to become entrapped in the soffit, some of that water is likely to evaporate and leave through the vents without outside intervention.

Code Requirements for New Construction

After the balcony collapse in Berkeley, there were also changes to building codes that require soffit vents for enclosed EEEs in new construction.

In 2015, the city passed laws governing the new construction of soffited balconies. Here is an excerpt concerning the installation of soffit vents:

Section 1203.6 Ventilation of weather exposed enclosed assemblies: Balconies, landings, decks, stairs and similar exterior projecting elements and appurtenances exposed to the weather and sealed underneath shall have cross ventilation for each separate enclosed space by ventilation openings protected against the entrance of rain and snow.

Blocking and bridging shall be arranged so as not to interfere with the movement of air. The net free ventilating area shall not be less than 1/150th of the area of the space ventilated. Ventilation openings shall comply with Section 1203.2.1. An access panel of sufficient size shall be provided on the underside of the enclosed space to allow for periodic inspection.

In early-2017, the State of California issued an emergency revision to the California Building code including the following requirement:

Section 2304.12.2.6 Ventilation required beneath balcony or elevated walking surfaces: Enclosed framing in exterior balconies and elevated walking surfaces that are exposed to rain, snow, or drainage from irrigation, shall be provided with openings that provide a net free cross ventilation area not less than 1/150 of the area of each separate space.

In 2018, the International Building Code (IBC) followed suit, incorporating the above sections.

Unlike the California Building Code, the IBC is adopted by multiple states across the country, making ventilation of EEEs and other requirements borne out of the Berkeley disaster the standard of care for the industry, moving forward.

Visual Inspection vs. Destructive Testing

California’s balcony inspection laws require “visual Inspection” of the wood-framed, load-bearing components for compliance. For the most part, we are encountering fully enclosed soffits, in which stucco or siding conceals the load-bearing components from view. In these circumstances, we have two options:

- Drill holes on the underside of the soffit and use a borescope (a small fiberoptic camera) as part of an unobtrusive and easy-to-patch visual inspection, or

- Perform destructive testing of the soffit

Destructive Testing (DT) is a process where finish materials (such as stucco) are removed, allowing the inspector to physically examine the exposed cavity, after which the opening must be patched by a qualified contractor. This method is often chosen if it is determined that the area of concern requires a further, more detailed inspection. Destructive testing can add significant costs, especially since the law requires re-inspection every six or nine years, depending on whether the project is governed by SB 721 or SB 326.

You can learn more about the definitions of key terminology found in California’s balcony laws here.

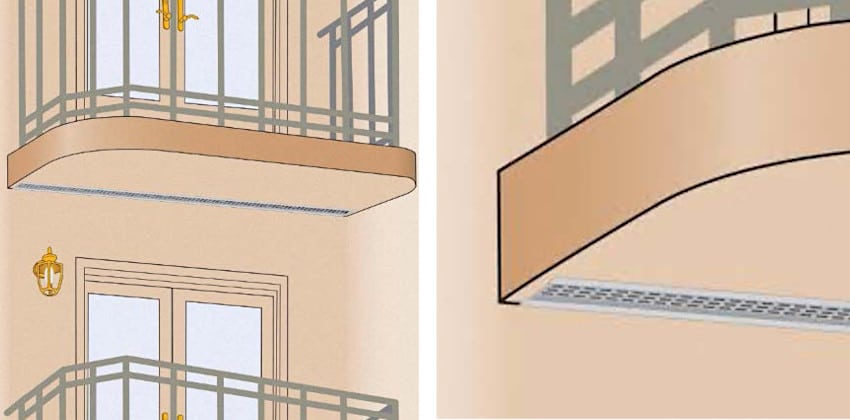

EEE Removable Vent Products

The combination of recent inspection laws and new construction venting laws has caused the building industry to come up with off-the-shelf, removable soffit vents. These can be included in architectural drawings and installed during construction or installed as part of the Destructive Testing (or repair) process on existing buildings. Here are a couple of examples of these products.

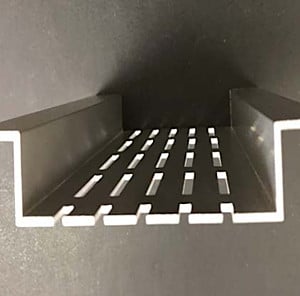

Stockton Products’ Removable Balcony Soffit Vent (RBSV)

This removable soffit vent permits access to the balcony soffit space for inspection at the balcony/wall transition and soffit space, while also providing free air movement and ventilation. In a retrofit application, a saw cut slightly larger than the reveal size is all that is required. The molding is then installed over the top of the opening and fastened to the joists with screws.

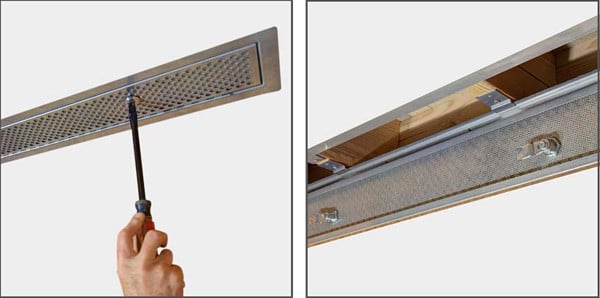

Balcony Inspection Vents

This removable soffit vent permits access to the balcony soffit space for inspection at the balcony/wall transition and soffit space, while also providing free air movement and ventilation. In a retrofit application, a saw cut slightly larger than the reveal size is all that is required. The molding is then installed over the top of the opening and fastened to the joists with screws.

Inspections Ideal Time to Make Fix

If destructive testing is determined to be the best means for further inspections, it may well be a cost-effective decision to incorporate removable venting into the balconies after the repairs are made. The benefits will be twofold: Future inspections will be quicker and easier, and the structures will be safer and more durable, by providing protection to the concealed wood framing inside the soffit. In fact, this is the code moving forward for new construction.

In summary, adding removable soffit vents to EEEs on existing multi-family buildings allows rapid temperature and vapor equalization, reducing the risk of interior water damage and slowing wood deterioration over time. A great time to make the fix is during the inspection process.

Author

Scott Riffenburgh, CEM, LEED-AP

Manager of Consulting Services, Xpera Group

This article was originally published by Xpera Group which is now part of The Vertex Companies, LLC.