Recently, we have seen an increase in the number of commercial property owners facing vapor intrusion concerns. If you are redeveloping a contaminated property, refinancing it, or leasing it to a corporation, vapor intrusion can be a big liability and cost.

What is Vapor Intrusion?

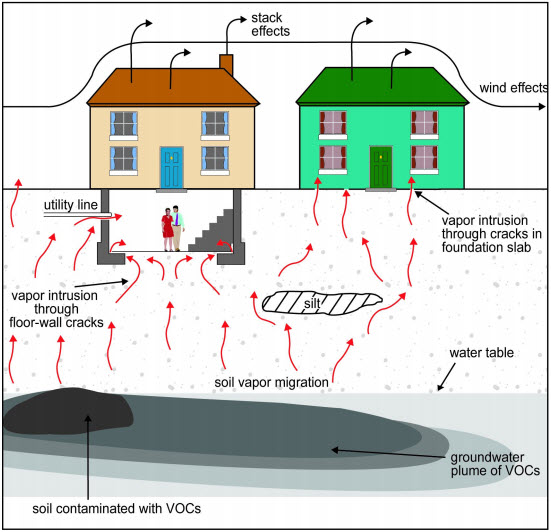

According to the US Environmental Protection Agency (EPA), vapor intrusion occurs when vapor-forming chemicals migrate from a subsurface source into an overlying building. Volatile chemicals from groundwater contamination or contaminated soil can enter a building through cracks or holes in the foundation slab or walls, utility penetrations, and/or can permeate through building materials. Vapor-forming chemical compounds typically include:

- Volatile organic compounds (VOCs), such as perchloroethylene and benzene;

- Select semi-volatile organic compounds, such as naphthalene;

- Inorganic chemicals, such as elemental mercury; and

- Gases, such as methane.

The figure below shows how the vapors in soil gas from contaminated soil and groundwater migrate into buildings.

State regulations often require the removal of the contaminant from the soil or groundwater and a sub-slab depressurization system (SSDS) may be needed to ensure short-term or long-term protection of building occupants against breathing the vapors from the contamination.

Sub-slab Depressurization Systems (SSDS) – Design

Upon the identification of a vapor intrusion concern, a sub-slab depressurization system for the control of indoor air vapor intrusion is likely to be required. The design of these systems can be complicated, especially in existing buildings in old commercial/industrial areas. For new buildings, the remediation engineer is working with a clean slate, although environmental issues sometimes take a backseat to other building design and construction concerns.

Design concerns may include:

- Construction materials

- Location of plumbing pipe runs

- Location of footings

- Interior and exterior noise concerns

- Location of roof-mounted structures

The sooner you can involve the remediation engineer the better.

Pilot Testing

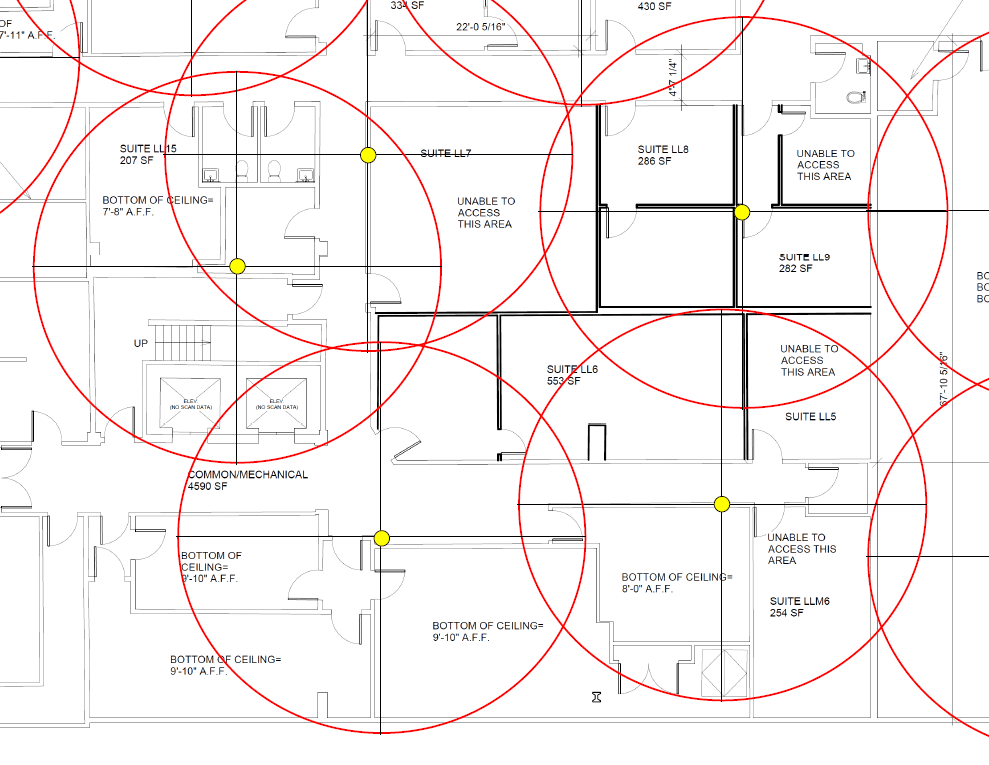

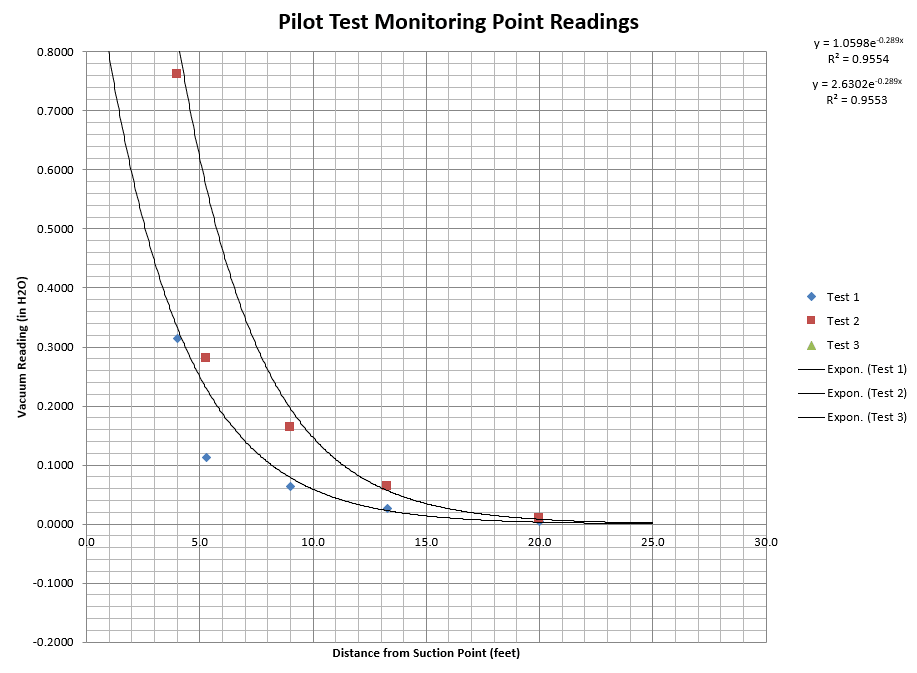

For existing buildings, sometimes the first question we ask ourselves is whether the project calls for the performance of a pilot test. As an engineer, having first-hand data is key to the design. Measurements collected during a pilot test allows for the determination of performance data that includes the calculated radius of influence, vacuum, and airflow rate. All of which allows for the determination of the type and placement of extraction points, the sizing of the blower, number of blowers, sizing of piping runs, materials of construction, etc. Knowledge of these parameters limits the variability in the design and allows for less assumptions and a greater chance of success. That said, a pilot test can be costly to perform.

For a smaller building, it may be more economical to install an additional riser(s), oversize the piping, or change out a blower versus performing a pilot test. For large projects, pilot tests are invaluable and can save time and money based on what is determined to be the radius of influence, flow rate, and vacuum. A pilot test may also reveal if there are below-grade structures that are impairing flow. Know that the cost of a pilot test is not always scalable as a small building may require the same number of pilot test points as a larger building.

Historic Data Review

Prior to performing a pilot test or completing a design, VERTEX engineers look at historic fire insurance maps, aerial photos, and topographic maps, geologic and soil survey maps, construction documents, and soil boring logs. Much information can be gathered from these sources that may be useful for the placement of pilot test extraction points or in the final design of the SSDS.

Vapor Intrusion Regulations and Requirements

Knowledge of the regulations and what leeway the design engineer has is very important. Some states require that the entire slab be depressurized. In most cases, this is not typically warranted to achieve protection of indoor air quality. Collection and analysis of sub-slab soil gas samples can pinpoint and allow for the targeting of a source. As the soil gas that is being sampled may have accumulated and reached a steady state over months or years, continuous removal of soil gas near a source or preferred pathway may be sufficient to prevent the spread of that gas over the larger building footprint. Knowledge of the source and below-grade conditions may be key to the design and cost savings.

How Can VERTEX Help?

Whether you are in need of services for a single asset or a full portfolio, VERTEX’s Environmental and Engineering Experts partner with you to resolve complex challenges across the real estate lifecycle.

To learn more about VERTEX’s Environmental Consulting services or to speak with an Environmental Expert, call 888.298.5162 or submit an inquiry.