What is Dry Cleaning?

Despite the name, dry cleaning operations are not actually “dry”. Instead, they involve the use of cleaning solvents, detergents, and some water. Historically, the cleaning solvent component consisted of perchloroethylene/tetrachloroethene, otherwise known as Perc or PCE. Since the 1990s, several non-chlorinated alternative solvents have been developed including, but not limited to petroleum-based, propylene glycol ether-based, and n-propyl bromide-based cleaners.

PCE Release Causes

Prior to the 1980s and 1990s, dry cleaning regulations were limited. As a result, good housekeeping within these facilities was not considered a high priority. Poor housekeeping and the lack of regulatory oversight partnered with the use of PCE often resulted in releases to the environment. The releases typically occurred due to the following:

- Poor housekeeping – PCE was not properly contained, the flooring was cracked or not epoxy-coated, and drippage during the transfer of wet garments from the machinery.

- Improper disposal – spent solvent and/or wastewater was flushed into the sewer system or tossed out of the back door of the facility, sludge and used filters were placed in regular trash rather than being disposed of properly.

- Failure of the machinery/secondary containment – older machines were not equipped with drip pans or were not closed-loop systems in which the solvent is contained within the system.

- Spills during delivery and/or removal of solvents and solvent-containing materials.

Why is PCE a Concern?

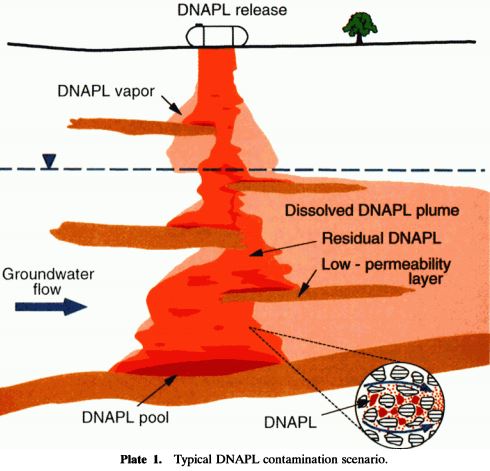

PCE is a colorless, non-flammable liquid with a sweetish smell. It evaporates easily but persists in the environment as it degrades into other chlorinated volatile organic compounds (CVOCs) such as trichloroethene (TCE). Due to the presence of one or more chlorine atoms, CVOCs are heavier than water and are commonly referred to as Dense Non-Aqueous Phase Liquid (DNAPL) or “sinkers”. Given these characteristics, PCE and its breakdown compounds may travel in the subsurface as DNAPL, in a dissolved phase in groundwater, and in a gaseous phase in soil vapor. Since PCE does not strongly sorb to soil, soil impacts are typically limited to the source area.

PCE Remedial Strategies

Since PCE and its breakdown compounds can persist in the environment, it is important that the impacts are fully delineated – this often requires installation of shallow and deep monitoring wells within the source area and downgradient of the plume to fully assess potential DNAPL and dissolved phase plumes. In states where vapor intrusion assessment is required, the investigation will also include soil vapor and indoor air sampling. Although remedial strategies vary based on site-specific subsurface and plume distribution characteristics, typical remedial approaches include:

- Enhanced In-Situ Bioremediation

- In-Situ Chemical Oxidation

- Groundwater Pump and Treat

- Air Sparge / Soil Vapor Extraction

- High Vacuum Dual Phase Extraction

- Thermal Injection

In general, cleaning up CVOC plumes is expensive and often requires a combination of remedial strategies to achieve regulatory closure.

How Can VERTEX Help?

VERTEX has a team of environmental professionals that have the appropriate training to investigate chlorinated solvent releases from dry cleaning operations, determine the necessary response activities, the extent of the impacts, identify any potentially responsible parties, and determine the appropriate remedial efforts and regulatory reporting necessary to correct the environmental condition.

To learn more about VERTEX’s Environmental Consulting and Environmental Claims Consulting services or to speak with an Environmental Expert, call 888.298.5162 or submit an inquiry.

Author: Lauri Fern Glinsky