In loss of productivity claims (“LOP”) or schedule delay claims, the impact to contractors and owners can be extremely costly, as well as contentious. There are several models used for tracking or calculating productivity impacts. In an ideal scenario, the impact on productivity is tracked in real-time with actual observations of lost productivity as they occur, making it possible to prepare an actual cost claim. In reality, though, it is a commonplace in litigated matters to attempt to quantify the effect of productivity impacts after the fact. This blog focuses on using industry studies, namely the Mechanical Contractors Association of America (MCAA) factors, to measure productivity impacts.

In this post, we look at

- Ways to apply the MCAA model in calculating claims and other instances

- An example of using the MCAA model

- Common mistakes in using the MCAA model

The MCAA List of Productivity Factors

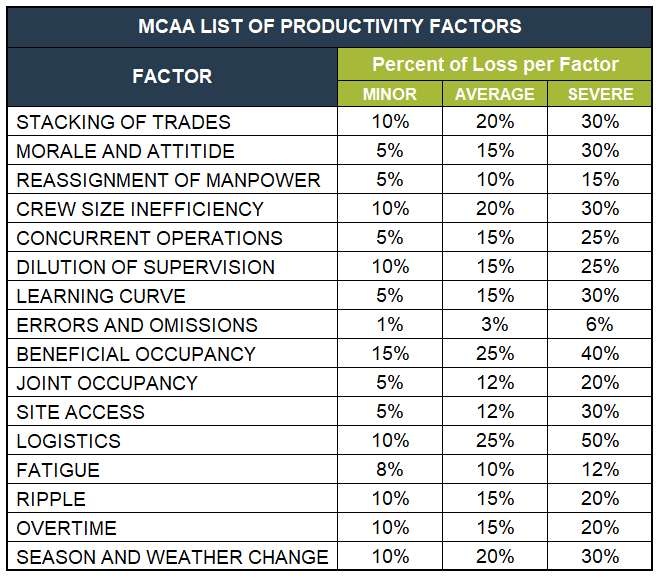

The MCAA first introduced its list of construction productivity factors in 1971. Since then, the model has gained significant acceptance in the industry. The list includes 16 factors that may affect productivity and a range of percentages of impact ranging from ‘minor’ to ‘average’ to ‘severe.’

- STACKING OF TRADES: Operations take place within physically limited space with other contractors. Results in congestion of personnel, inability to locate tools conveniently, increased loss of tools, additional safety hazards and increased visitors. Optimum crew size cannot be utilized.

- MORALE AND ATTITIDE: Excessive hazard, competition for overtime, over-inspection, multiple contract changes and rework, disruption of labor rhythm and scheduling, poor site conditions, etc.

- REASSIGNMENT OF MANPOWER: Loss occurs with move-on, move-off men because of unexpected changes, excessive changes, or demand made to expedite or reschedule completion of certain work phases. Preparation not possible for orderly change.

- CREW SIZE INEFFICIENCY: Additional workers to existing crews “breaks up” original team effort, affects labor rhythm. Applies to basic contract hours also.

- CONCURRENT OPERATIONS: Stacking of this contractor’s own force. Effect of adding operation to already planned sequence of operations. Unless gradual and controlled implementation of additional operations made, factor will apply to all remaining and proposed contract hours.

- DILUTION OF SUPERVISION: Applies to both basic contract and proposed change. Supervision must be diverted to (a) analyze and plan change, (b) stop and re-plan affected work, take-off, order and expedite material and equipment, (d) incorporate change into schedule, (e)instruct foreman and journeyman, (f) supervise work in progress, and(g) revise punch lists, testing and start-up requirements.

- LEARNING CURVE: Period of orientation in order to become familiar with changed condition. If new men are added to project, effects more severe as they learn tool locations, work procedures, etc. Turnover of crew.

- ERRORS AND OMISSIONS: Increases in errors and omissions because changes usually performed on crash basis, out of sequence or cause dilution of supervision or any other negative factors.

- BENEFICIAL OCCUPANCY: Working over, around or in close proximity to owner’s personnel or production equipment. Also badging, noise limitations, dust and special safety requirements and access restrictions because of owner. Using premises by owner prior to contract completion.

- JOINT OCCUPANCY: Change cause work to be performed while facility occupied by other trades and not anticipated under original bid.

- SITE ACCESS: Interferences with convenient access to work areas, poor man-lift management or large and congested worksites.

- LOGISTICS: Owner furnished materials and problems of dealing with his storehouse people, no control over material flow to work areas. Also contract changes causing problems of procurement and delivery of materials and re-handling of substituted materials at site.

- FATIGUE: Unusual physical exertion. If on change order work and men return to base contract work, effects also affect performance on base contract.

- RIPPLE: Changes in other trades’ work affecting our work such as alteration of our schedule. A solution is to request, at first job meeting, that all change notices/bulletins be sent to our Contract Manager.

- OVERTIME: Lowers work output and efficiency through physical fatigue and poor mental attitude.

- SEASON AND WEATHER CHANGE: Either very hot or very cold weather, or storm events.

How to Apply MCAA Factors

To correctly apply the MCAA factors, one must carefully consider which factor(s) and percent of loss per factor are most applicable to the impacted window of time. Contemporaneous documents that recorded the impacts should be relied on, as well as input from personnel who witnessed the conditions.

Generally, the MCAA model is used to corroborate a LOP claim that is prepared using other listed methods or when other methods are not applicable. Contractors can also use the MCAA factors in a prospective or forward-looking manner when estimating change orders.

The MCAA factors are applied to the expected labor hours for a given task or scope of work. The percent of loss per factor must not be applied to the actual hours worked because the loss of productivity will be overstated. If no record of the estimated hours for an impacted scope of work exists, actual hours must be adjusted to remove:

- Time and Material hours

- Hours accrued to correct the contractor’s defective work

- Hours accounted for in change orders unrelated to the productivity impacts

- Hours associated with executed change orders or other contract work which bars the contractor from recovering the productivity impact

- Hours expended by crews which were not affected by a loss of productivity

- Other types of productivity loss for which the contractor is responsible

Once the expected number of labor hours has been correctly identified and the relevant factors and percent of loss for the selected factor is chosen, the percentages are added together to calculate an overall impact percentage. The following example is a simple forward pricing exercise that utilizes anticipated or known factors.

Example:

- A change order without impacts is expected to cost 1000 labor hours.

- The changed condition necessitates that additional crews be assigned to the project.

- The contractor then selects applicable MCAA factors and percent of loss per factor:

- Crew Size Inefficiency Minor 10%

- Learning Curve Minor 5%

- Reassignment of Manpower Average 10%

- The percentages are added together (25%) and multiplied by the expected hours.

- 1000 hours x 25% = 250 hours of production lost to inefficiencies.

- The anticipated hours lost are then added to the un-impacted estimate to arrive at the total required hours to perform this work: 1000 hours + 250 hours = 1,250 hours

What You Need to Know When Applying the MCAA Factors

The most common mistakes when utilizing the MCAA factors include:

- Applying MCAA factors to time periods that did not experience the impacting condition(s).

- For example, incorrectly applying “Overtime” to the hours stipulated by the contract.

- Applying MCAA factors retroactively to labor hours included in change orders which previously had forward priced LOP hours included in the change order. NO DOUBLE-DIPPING!

- Applying some factors in conjunction with others.

- For example, “Overtime Fatigue” already includes a loss factor for “Decreased Morale and Attitude.”

- Additionally, consider the “Ripple Effect” when striving to avoid duplicitous factors. For example, do not include factors for “Diluted Supervision” when attempting to recover additional supervision costs.

How Can Vertex Help?

When evaluating loss of productivity claims and providing expert opinions on the same litigated matters, VERTEX considers various industry-accepted models, including the MCAA factors, to estimate losses. VERTEX can also testify and prepare claims in accordance with the industry-accepted methods described above when beneficial for reference in a litigated setting.

If you’d like to learn more about VERTEX’s Expert Services or speak with an Engineering Expert, call 888.298.5162 or submit an inquiry.